NM01CEG01124U0202

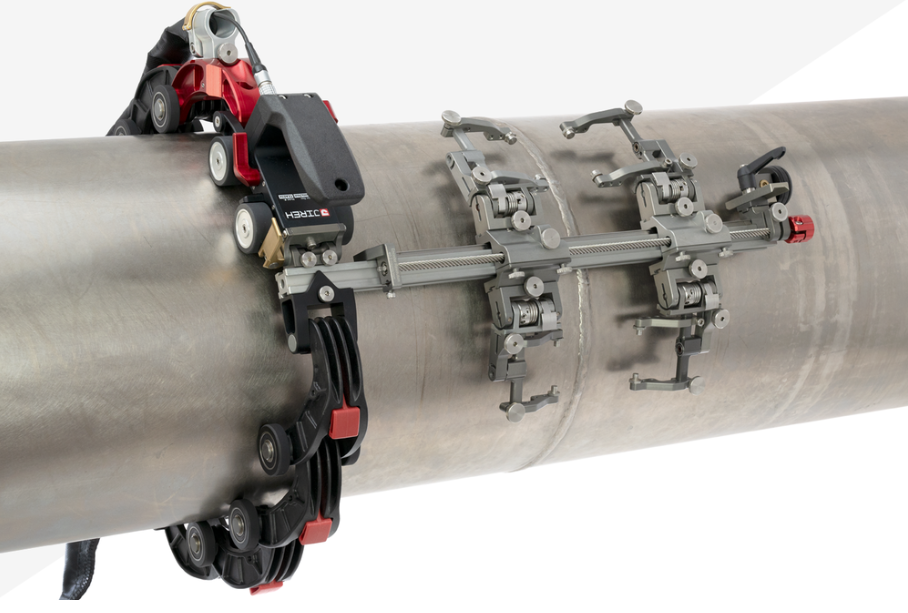

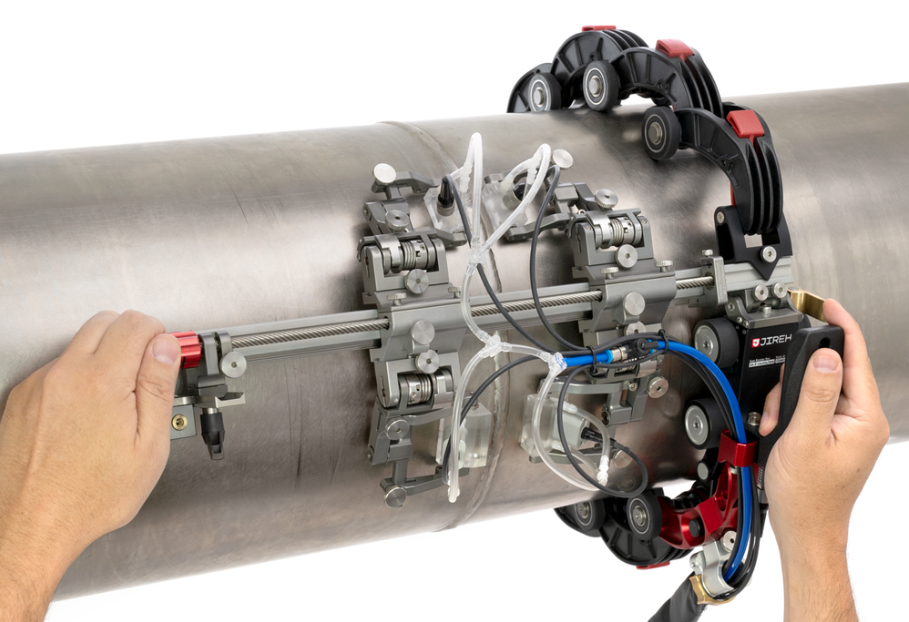

ROTIX - 4 Probe Weld Scanner w/ PPS, chain size: 3.8 - 60 cm, (1.5 - 24") diameter, encoder conector type: Sonatest VEO / Prisma, primary pivot buttons: 5.0 mm (0.197"), secundary pivot buttons: 5.0 mm (0.197"). JIREH

Maximize Weld Inspection Efficiency with the JIREH ROTIX - 4 Probe Weld Scanner with PPS!

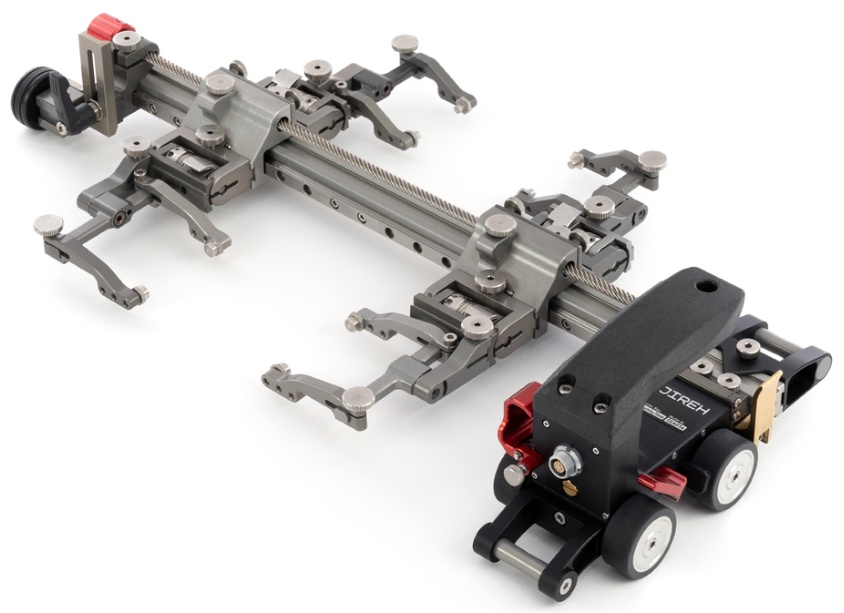

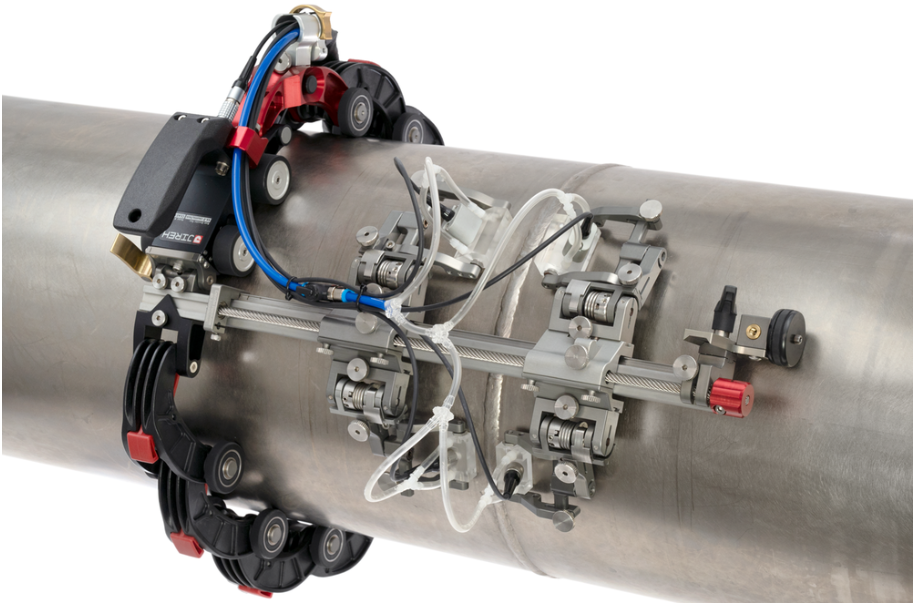

The JIREH ROTIX - 4 Probe Weld Scanner with PPS (Probe Positioning System) is a robust and versatile manual scanner designed to streamline ultrasonic inspection of circumferential welds on pipes and cylindrical vessels. This scanner allows for simultaneous mounting of up to four ultrasonic probes, significantly increasing inspection speed and data acquisition efficiency.

Key Features for Enhanced Weld Inspection:

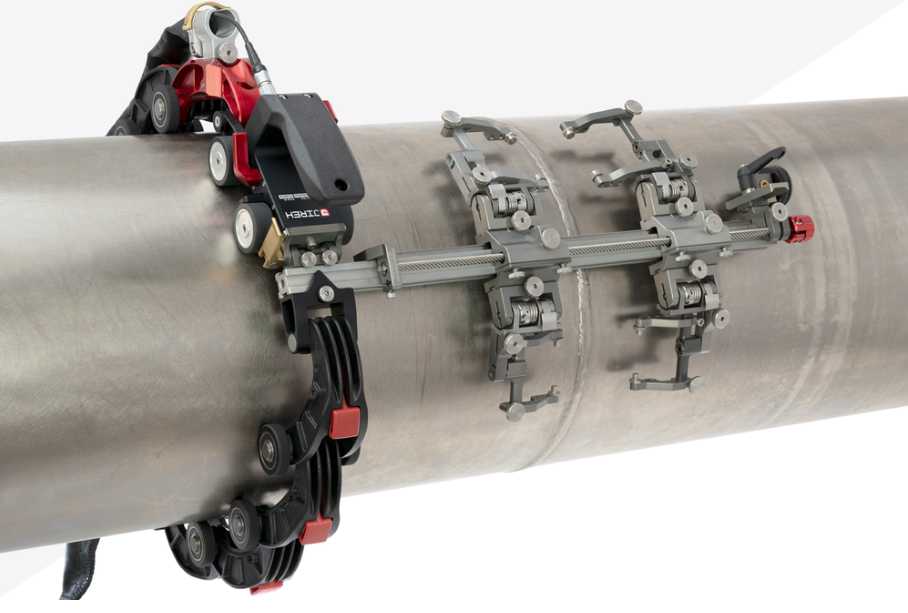

Four-Probe Capability: Accommodates up to four ultrasonic probes for comprehensive weld coverage in a single pass, dramatically reducing inspection time.

Wide Diameter Range: Easily adjustable chain system fits pipe and vessel diameters from 1.5 inches (3.8 cm) up to 24 inches (60 cm), offering versatility for various inspection tasks.

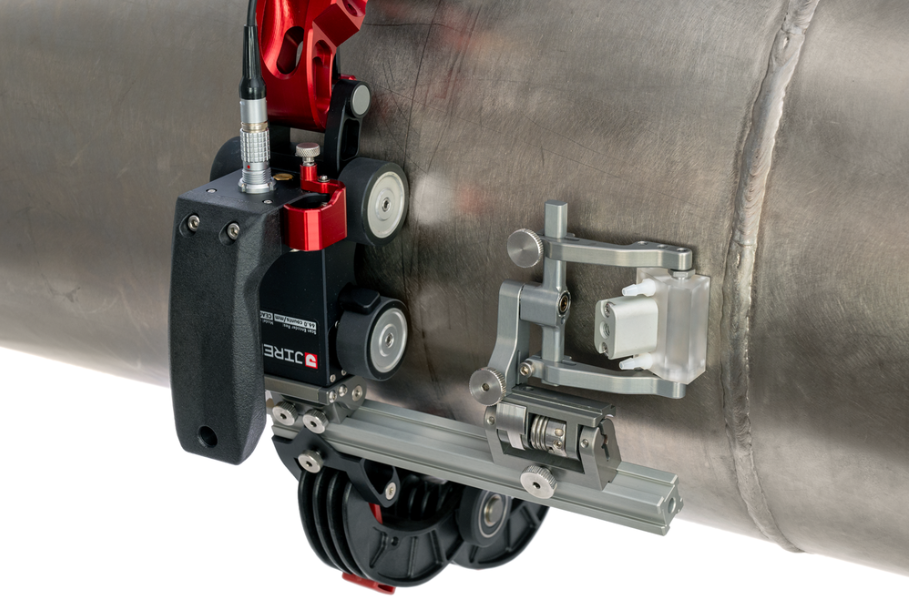

Precise Probe Positioning System (PPS): Ensures accurate and repeatable probe placement and tracking along the weld seam for reliable data acquisition.

Encoder Compatibility: Features an encoder connector compatible with Sonatest VEO / Prisma instruments, enabling precise positional data for advanced data analysis and mapping.

Durable Construction: Built with high-quality materials to withstand demanding inspection environments, ensuring long-lasting performance.

User-Friendly Design: Intuitive setup and operation make it easy for technicians to deploy and utilize effectively.

Precise Pivot Buttons: Equipped with primary and secondary pivot buttons of 5.0 mm (0.197") for stable and consistent probe articulation.

Complete Package: Includes the ROTIX scanner, Probe Positioning System, adjustable chain, encoder connector, pivot buttons, and a high-impact carrying case for secure transportation and storage.

Benefits for Your Inspection Workflow:

Increased Inspection Speed: Inspect more weld length in less time with the ability to deploy multiple probes simultaneously.

Improved Data Quality: Precise probe positioning and tracking ensure consistent and reliable ultrasonic data.

Enhanced Coverage: Easily configure probe arrangements to achieve comprehensive inspection of the weld volume.

Versatile Application: Suitable for a wide range of pipe and vessel diameters across various industries.

Durable and Reliable: Built to withstand the rigors of field inspections.

Easy to Use: Designed for efficient setup and operation by NDT technicians.