NM01BTG006BK06

MICROBE - 2 Probe Weld Scanner, Encoder Connector Type, Sonatest Prisma, Probe Pivot Buttons, 3.0 mm (0.118 in). JIREH

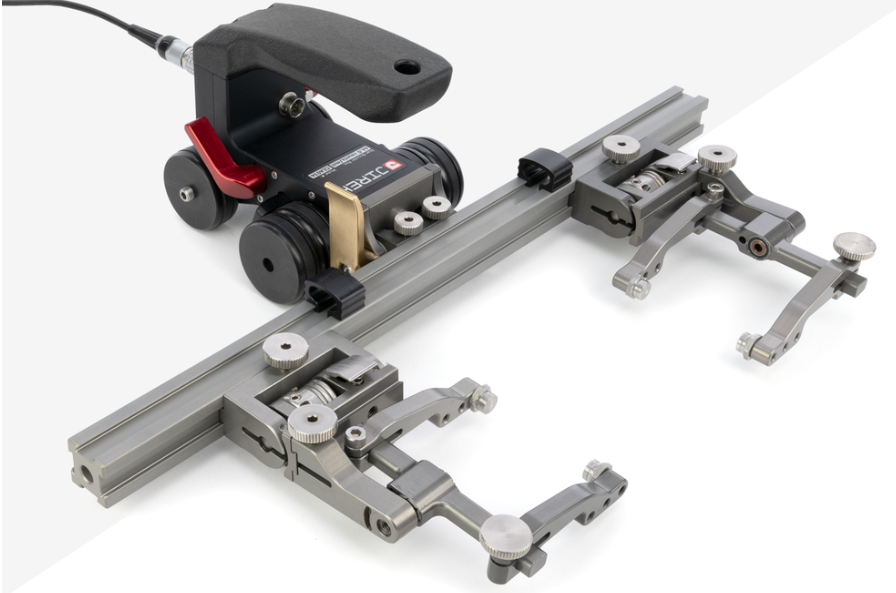

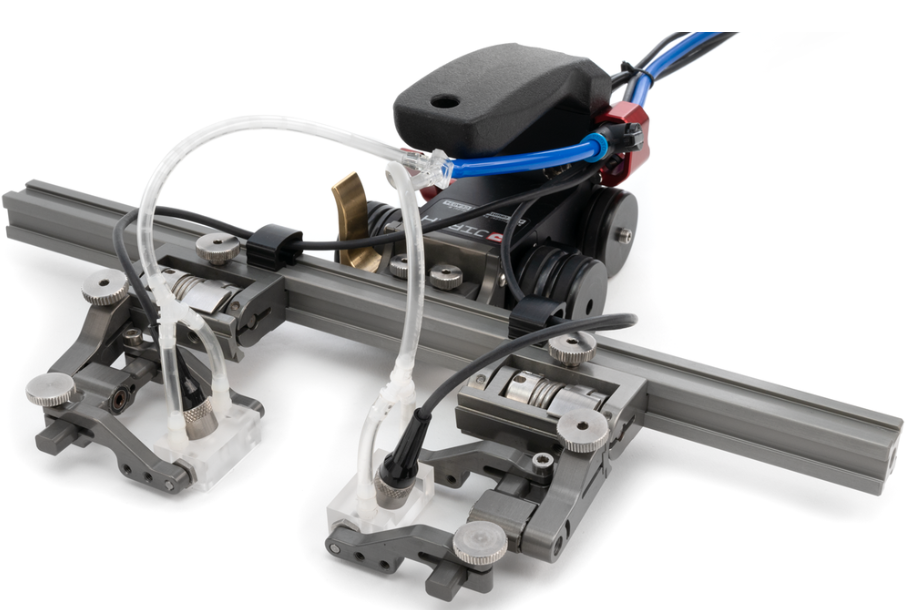

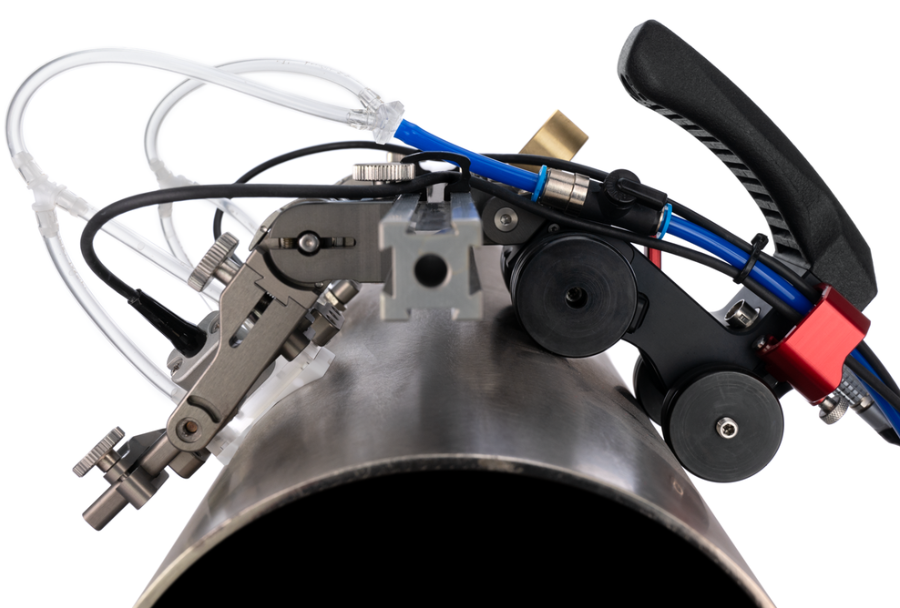

The JIREH MICROBE - 2 Probe Weld Scanner is a compact and versatile manual scanner engineered for efficient and accurate ultrasonic inspection of welds when used with compatible ultrasonic flaw detectors. This scanner is designed to simultaneously accommodate two probes, making it well-suited for a variety of advanced ultrasonic techniques, including Phased Array and Time-of-Flight Diffraction (TOFD).

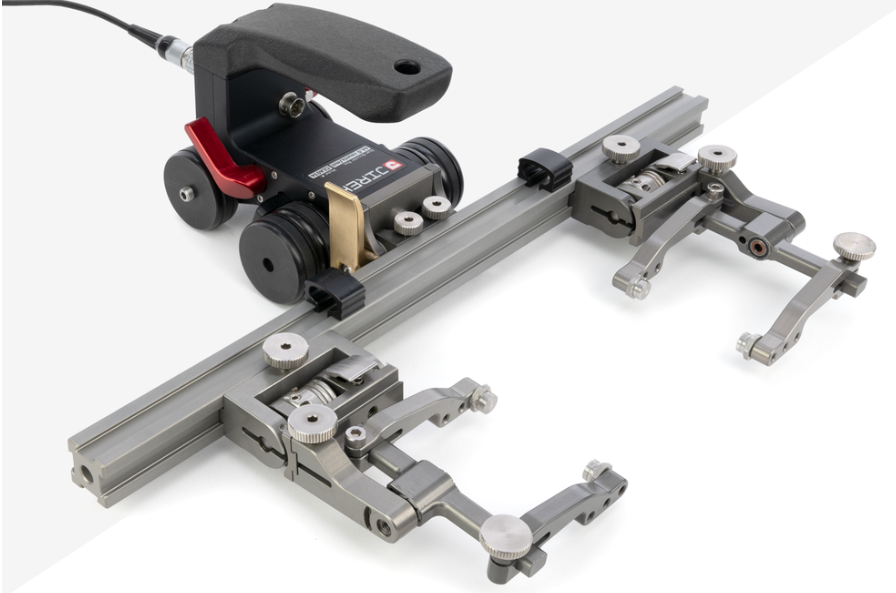

Featuring a precise encoder connector type for seamless integration with compatible flaw detectors, the MICROBE ensures accurate positional data acquisition during scanning. The inclusion of probe pivot buttons allows for easy and precise articulation and adjustment of the probe angles, optimizing coupling and coverage for different weld geometries.

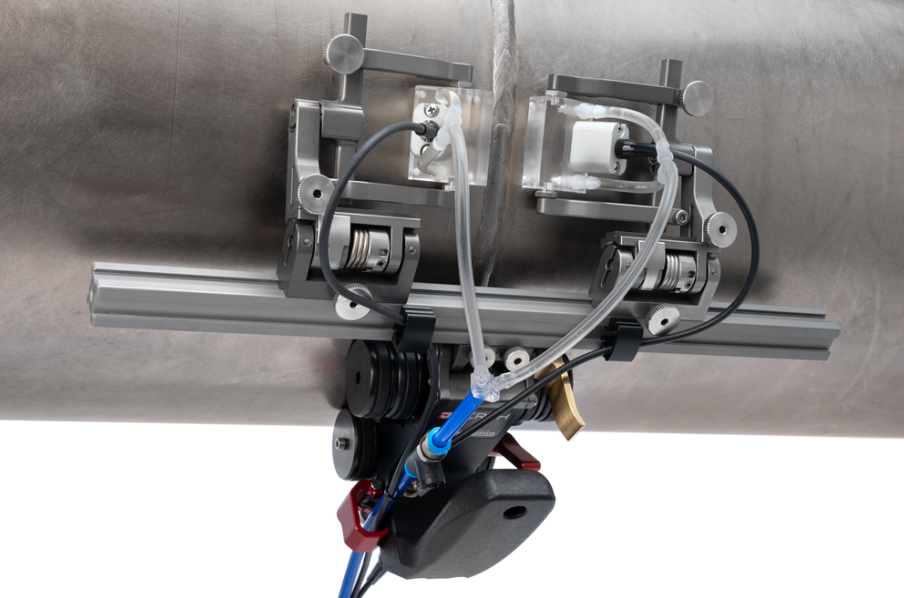

The scanner incorporates a fixed 3.0 mm (0.118 in) standoff, providing consistent probe distance from the inspection surface, which is crucial for reliable and repeatable ultrasonic testing. Its ergonomic and low-profile design enables access to restricted areas and comfortable operation during extended inspections. Magnetic wheels ensure stable and smooth scanning on ferrous materials.

Key Selling Points:

Dual Probe Capability: Accommodates two probes for efficient Phased Array, TOFD, or combined technique inspections.

Precise Encoder Integration: Provides accurate positional data for reliable scanning and imaging with compatible flaw detectors.

Adjustable Probe Pivots: Allows for optimal probe angulation and coupling on various weld profiles.

Consistent 3.0 mm Standoff: Ensures repeatable and reliable ultrasonic measurements.

Compact and Ergonomic Design: Enables access to tight spaces and comfortable operation.

Magnetic Wheels: Provides stable and smooth scanning on ferrous materials.

Durable Construction: Built to withstand demanding inspection environments.

Benefits:

Enhanced Weld Inspection Efficiency: Inspect more area in less time with dual probe capability.

Accurate Defect Detection and Sizing: Precise encoder feedback and probe positioning contribute to reliable results.

Versatile Application: Suitable for a wide range of weld types and inspection techniques.

Improved Data Quality: Consistent standoff optimizes ultrasonic coupling and signal quality.

Increased Productivity: Ergonomic design minimizes operator fatigue during long scans.

Applications:

The JI REH MICROBE - 2 Probe Weld Scanner is ideal for ultrasonic weld inspection in various industries, including:

Oil and Gas (pipeline and vessel welds)

Aerospace (structural weld inspection)

Manufacturing (quality control of welded components)

Power Generation (weld inspection in critical structures)

Construction (inspection of structural welds)

This JI REH MICROBE - 2 Probe Weld Scanner offers a high-performance solution for accurate and efficient ultrasonic weld inspection, providing precise encoder feedback, adjustable probe positioning, and a consistent standoff for reliable results when used with compatible ultrasonic flaw detection equipment.