NM01CEG00212U02

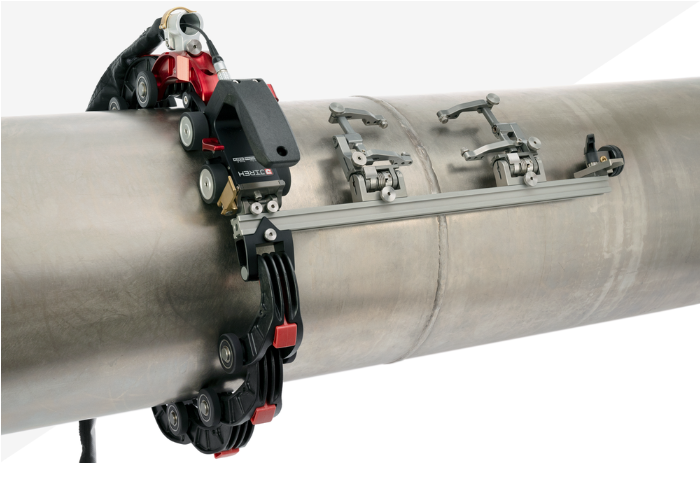

JIREH Rotix - 2 Probe Phased Array Scanner - Pipe Inspection System (1.5" - 12" Dia.)

Revolutionize your pipe inspection capabilities with the JIREH Rotix - 2 Probe Phased Array Scanner. Engineered for precision, speed, and versatility, this robust scanner system is designed for high-resolution ultrasonic testing of circumferential pipe welds and corrosion mapping on a wide range of pipe diameters. Compatible with Sonatest VEO/Prisma instruments and built for demanding field conditions, the Rotix streamlines your inspection process and delivers accurate, repeatable data.

Key Features & Benefits:

Dual Probe Capability: The Rotix is designed to accommodate two probes simultaneously. This enables:

Combined PAUT and TOFD (Phased Array Ultrasonic Testing and Time-of-Flight Diffraction): Maximizing flaw detection and sizing capabilities in a single pass.

Dual PAUT Scans: Increasing coverage or enabling specialized techniques with two phased array probes.

Wide Diameter Range: Specifically designed to scan pipes with outer diameters ranging from 3.8 cm to 30 cm (1.5 inches to 12 inches). This broad compatibility makes it suitable for a significant portion of pipeline and process piping inspections.

High-Resolution Encoding: Features a precise encoder for accurate positional tracking, ensuring high-fidelity data mapping for B-scan and C-scan imaging. This allows for detailed reporting and reliable flaw location.

Direct Sonatest VEO / Prisma Compatibility: Comes equipped with an encoder connector specifically designed for direct plug-and-play integration with Sonatest's advanced VEO and Prisma series phased array instruments. This simplifies setup and ensures seamless data acquisition.

Magnetic Wheel Design with 5mm Pivot Buttons: The scanner utilizes strong magnetic wheels for secure attachment and smooth travel along ferrous pipes. The 5 mm (0.197 in) pivot buttons enhance stability and grip, adapting well to surface variations and ensuring consistent coupling.

Robust and Lightweight Construction: Built with durable materials to withstand harsh industrial environments, yet designed to be lightweight enough for easy portability and single-operator deployment in the field.

Flexible Probe Mounting: Adjustable probe holders accommodate various wedge designs and probe configurations, allowing for customization to specific inspection requirements.

Efficient Operation: The ergonomic design and smooth tracking minimize operator fatigue and maximize inspection efficiency, reducing downtime and operational costs.

Typical Applications:

Circumferential weld inspection on pipelines, pressure vessels, and storage tanks.

Corrosion mapping and wall thickness profiling on pipes.

Flaw detection in new construction and in-service inspections.

Oil & Gas, Power Generation, Chemical Processing, and Fabrication industries.