NM01USR01

The OKO USR-01 Rail Welded Joint Testing Kit is a comprehensive solution specifically designed for the ultrasonic inspection of aluminothermic and electro-contact welded rail joints. This kit is engineered to ensure the integrity and safety of railway tracks by enabling thorough detection of potential defects in accordance with the EN14730-1:2006+A1:2010 standard.

The USR-01 kit is a valuable tool for railway maintenance and quality control teams, allowing for both initial weld inspection and secondary checks based on the results of high-speed mechanized ultrasonic testing systems. It also facilitates pre-weld inspection of rail ends, ensuring the quality of materials before the welding process.

Key Components of the USR-01 Kit (Contents may vary, but typically include):

Sonocon B Ultrasonic Flaw Detector: A user-friendly and robust handheld flaw detector offering all the necessary functions for inspecting welded rail joints. It complies with quality requirements and provides a range of standard and advanced inspection features. Its lightweight and ergonomic design ensures comfortable operation in the field.

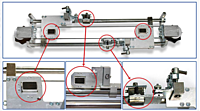

USR-01 Scanner: A specialized scanning device designed for precise positioning and controlled movement of ultrasonic probes along the welded joint. This ensures consistent and comprehensive coverage of the inspection area.

Combined Angle Beam Transducers: A set of transducers with specific angles (commonly 45° and 70° at 2 MHz) designed to inspect various zones of the rail weld, including the web and head, using the echo and pulse-echo methods. The specific transducer configuration is tailored to meet the requirements of EN14730-1.

Couplant: A necessary medium to ensure effective transmission of ultrasonic waves between the transducer and the rail.

Cables and Connectors: High-quality cables to connect the transducers to the Sonocon B flaw detector.

Carrying Case: A durable and protective case for easy transportation and storage of the complete kit.

Calibration Blocks/Standards: Essential for calibrating the ultrasonic equipment to ensure accurate and reliable test results according to the EN standard.

Operating Manuals and Documentation: Comprehensive instructions for the proper use and maintenance of the equipment, as well as guidance on inspection procedures according to EN14730-1.

Key Selling Points:

Compliant with EN14730-1:2006+A1:2010: Specifically designed to meet the requirements of the European standard for ultrasonic testing of railway welded joints.

Comprehensive Testing Solution: Provides all the necessary equipment for thorough inspection of aluminothermic and electro-contact welds.

Includes User-Friendly Flaw Detector: The Sonocon B offers a wide range of functions and an easy-to-operate interface for efficient testing.

Ensures Rail Safety and Integrity: Enables the detection of critical defects that could compromise the safety and longevity of railway tracks.

Suitable for Various Inspection Stages: Can be used for initial inspection, secondary checks, and pre-weld material assessment.

Portable and Robust: Designed for reliable performance in demanding field conditions.

Benefits:

Ensures Regulatory Compliance: Facilitates testing according to the required European standard.

Improved Rail Safety: Enables early detection of flaws, preventing potential rail failures.

Enhanced Efficiency: The scanner and user-friendly software streamline the inspection process.

Cost-Effective Solution: A complete kit designed specifically for rail weld inspection.

Durable and Reliable Equipment: Built to withstand the rigors of railway maintenance.

Applications:

Ultrasonic inspection of aluminothermic welded rail joints.

Ultrasonic inspection of electro-contact welded rail joints.

Secondary inspection of rail tracks following high-speed mechanized testing.

Pre-weld inspection of rail ends to ensure material quality.

Quality control during railway construction and maintenance.

The OKO USR-01 Rail Welded Joint Testing Kit is an indispensable tool for ensuring the safety and integrity of railway infrastructure. By providing a complete and EN14730-1 compliant solution for ultrasonic inspection of welded rail joints, it empowers railway maintenance teams to effectively detect and address potential defects, contributing to safer and more reliable railway transportation.