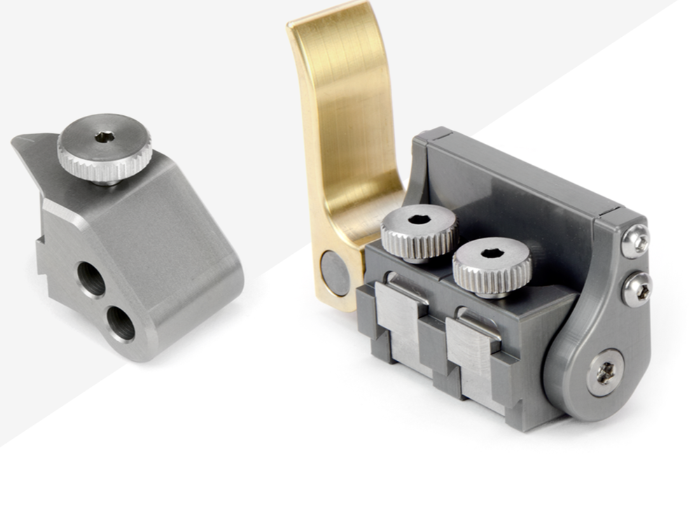

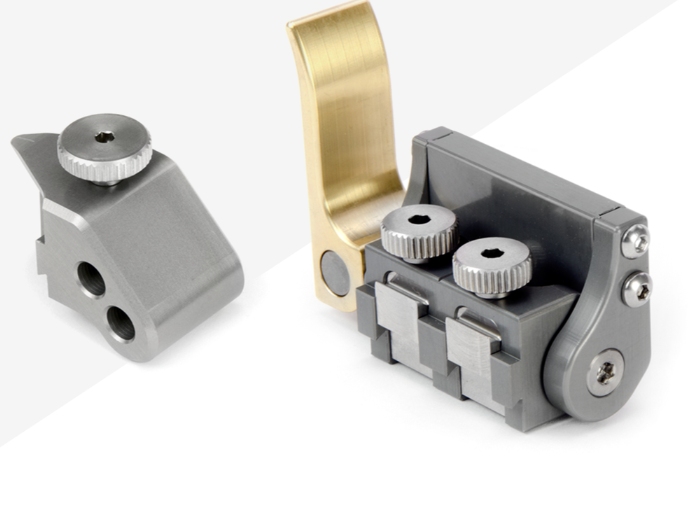

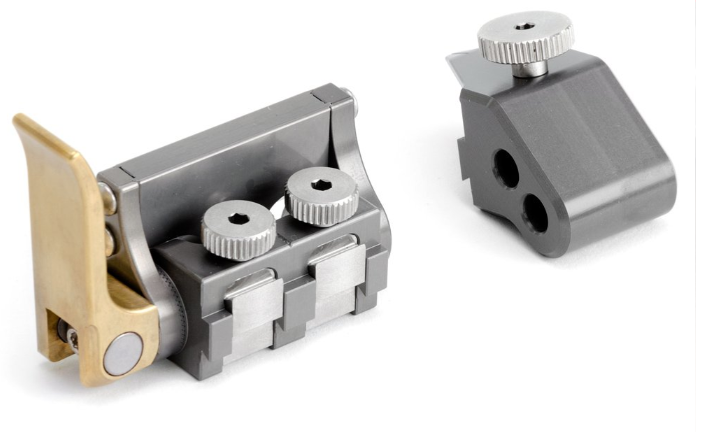

NM01CEG030

A Pivot Nose Upgrade Kit is a comprehensive set of precision-engineered components designed to enhance the performance and longevity of a pivot nose assembly within a mechanical system. This kit is intended to replace or augment existing pivot nose components, resulting in improved accuracy, durability, and operational efficiency.

Key Features:

Enhanced Precision Components: The kit typically includes upgraded bearings, bushings, or other critical components designed to minimize friction and backlash, leading to more precise and repeatable pivoting motions.

Reinforced Structural Elements: The pivot nose itself, or related structural components, may be replaced or reinforced to withstand increased loads, vibrations, or environmental stressors.

Improved Adjustment Mechanisms: The kit may incorporate precision adjustment screws, shims, or other mechanisms that allow for finer control over pivot angles or positions.

Durable Materials and Coatings: Components within the kit are often manufactured from high-strength alloys or feature wear-resistant coatings to extend the lifespan of the pivot assembly.

Sealing and Protection: Upgraded seals or protective covers may be included to prevent the ingress of contaminants, ensuring smooth and reliable operation in demanding environments.

Comprehensive Hardware and Instructions: The kit includes all necessary fasteners, gaskets, and detailed installation instructions to facilitate a seamless upgrade process.

Applications:

Automated Inspection Systems: Used to improve the accuracy and reliability of probe positioning in robotic or automated inspection systems.

Precision Manufacturing Equipment: Enhances the performance of pivoting mechanisms in manufacturing machinery, leading to improved product quality.

Robotic Systems: Upgrades the pivoting joints in robotic arms or manipulators, resulting in increased accuracy and efficiency.

Scanning and Measurement Devices: Improves the precision of pivoting components in scanning or measurement equipment.

Any Mechanical System with a pivot point that needs improved performance.

Importance:

Increased Accuracy and Repeatability: Upgraded components minimize play and friction, leading to more precise and repeatable pivoting motions.

Enhanced Durability and Reliability: Reinforced components and durable materials extend the lifespan of the pivot assembly, reducing downtime and maintenance costs.

Improved Operational Efficiency: Reduced friction and improved control mechanisms contribute to smoother and more efficient operation.

Extended Equipment Lifespan: Upgrading worn or damaged components can extend the overall lifespan of the equipment.