NM01NanoScan2Kit4

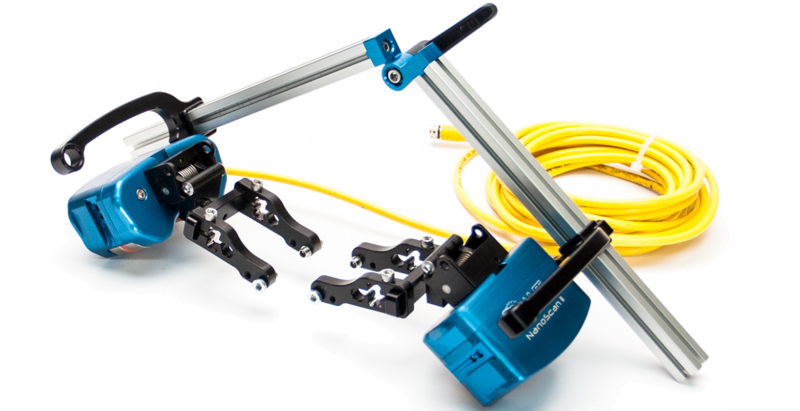

The AUT Solutions NanoScan2 Kit-4 is a comprehensive package designed for manual ultrasonic scanning, particularly for applications like corrosion mapping and weld inspection. It provides the essential hardware components for effectively deploying various ultrasonic testing techniques.

Key Components Included in the Kit-4:

Encoded Truck Assembly: This is the primary scanning unit equipped with an encoder. The encoder provides precise positional feedback, crucial for creating accurate C-scans and other data representations.

Secondary Truck Assembly (Idler Truck): This un-encoded truck works in conjunction with the encoded truck to provide stability and maintain consistent probe contact during scanning.

2 x Gimbles: Gimbles are pivoting supports that hold the ultrasonic probes and wedges. They allow the probes to maintain proper contact with the inspection surface, even on curved or irregular geometries. Two gimbles offer versatility for different inspection setups, potentially allowing for dual probe configurations.

Nozzle Kit: This kit likely includes components for attaching a couplant delivery system (e.g., a bubbler or squirter) to the scanner. Proper couplant application is essential for effective ultrasonic signal transmission into the test material.

Shipping Case: A durable case designed to protect and transport all the components of the NanoScan2 Kit-4, ensuring safe handling and storage.

Key Features and Benefits of the NanoScan2 System (General, based on available information):

Manual Scanner: Designed for handheld operation, offering flexibility and adaptability for various inspection tasks.

Encoded: The inclusion of an encoder allows for precise data indexing and the creation of detailed ultrasonic maps (B-scans, C-scans).

Magnetic Wheels (likely): AUT Solutions scanners often feature magnetic wheels for strong adhesion to ferrous materials, enabling scanning on vertical or inverted surfaces.

Versatile Probe Holding: The gimbles are designed to accommodate various conventional and advanced ultrasonic probes and wedges (including phased array and TOFD).

Compatible with Multiple Instruments: AUT Solutions scanners are typically designed to work with flaw detectors from various manufacturers (e.g., Sonatest, Olympus, GE, etc.).

Portable and Durable: Built for use in demanding inspection environments.

Applications:

Manual ultrasonic corrosion mapping.

Weld inspection using various ultrasonic techniques (conventional UT, phased array UT, TOFD).

Thickness gauging and flaw detection on ferrous materials.

Inspection of pipes, vessels, and other components with complex geometries.