OKOndt OKOSCAN 73HS High-Speed Rail Testing System

The OKOSCAN 73HS System is intended for automated high-speed testing of rail in service.

Have questions about buying this product?

This ultrasonic rail inspection equipment allows detecting all types of fatal defects: transverse and longitudinal horizontal cracks, cracks from bolt holes, etc.

The OKOSCAN 73HS kit includes:

- a flaw detection trolley

- 4 wheel probes

- OKO-24 ultrasonic modules (24 pcs minimum)

- an encoder

- a PC with special-purpose software.

The system ensures testing at a speed of up to 40 km/h (25 miles).

Trolley (Carriage)

The testing trolley assures the positioning and movement of the wheel probes. Electric drives mounted onto the trolley serve for an automatic adjusting of the trolley

to the gauge type (track width). It is an auxiliary mechanism which helps to center the wheel probes along the rail axis.

Key features of the flaw detection trolley:

- capability to test curves with a radius of less than 200 m (at a lower testing speed – of no less than 120 m)

- prompt automatic width adjustment to the gauge type

- ease of maintenance

- capability to control the suspension system (cant).

Wheel probes

The ultrasonic rail testing System incorporates four (4) wheel probes. Each probe includes:

- three 70-degree transducers, 2 MHz

- one 45-degree transducer, 2 MHz

- one 40-degree transducer, 2 MHz (Side looking)

- one 0-degree transducer, 4 MHz

- two 58-degree transducer, 2 MHz (Side looking).

Ultrasonic modules

The OKOSCAN 73HS System utilizes OKO-24 single-channel ultrasonic modules with a frequency range from 1 to 7 MHz and initial pulse sending frequency of up to 4 kHz.

The OKOSCAN 73HS structure envisages two positioning options of the ultrasonic modules:

- Directly on the trolley. This positioning option provides for better protection against interference, wheel probe connection cables to the ultrasonic modules have a smaller length, data from the module to the PC are transferred through the Ethernet cable.

- In the vehicle. This variant of positioning releases from an additional load and decreases the trolley weight, ultrasonic modules are protected from external climatic conditions impact.

Special-purpose software

The OKOSCAN 73HS high-speed rail flaw detector is supplied with the pre-installed software. The software is composed of:

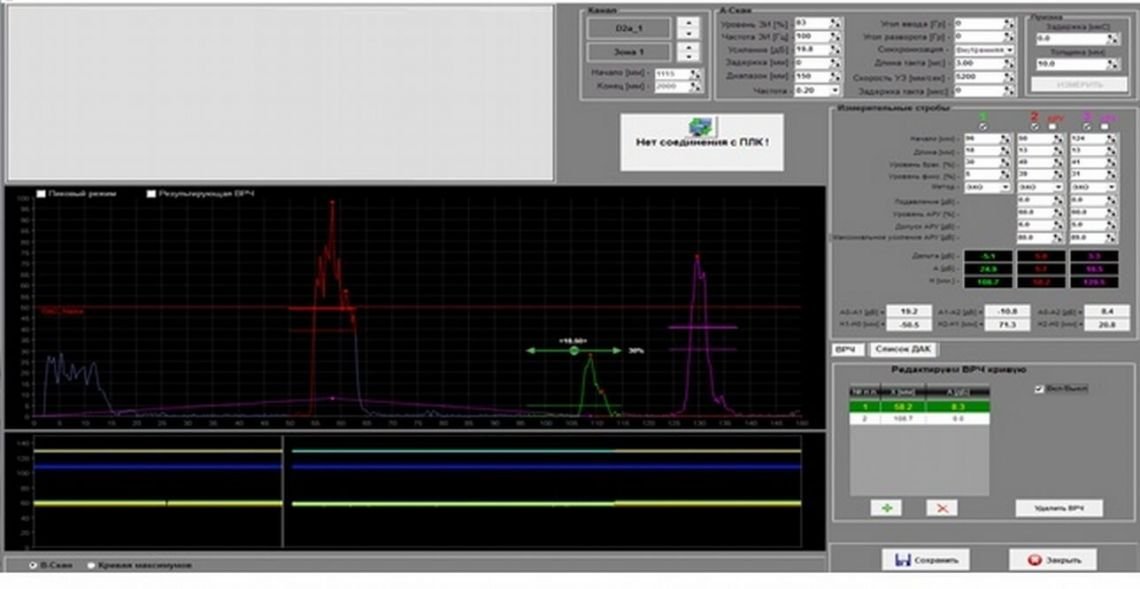

SW for the channel parameters setup

SW for the channel parameters setup

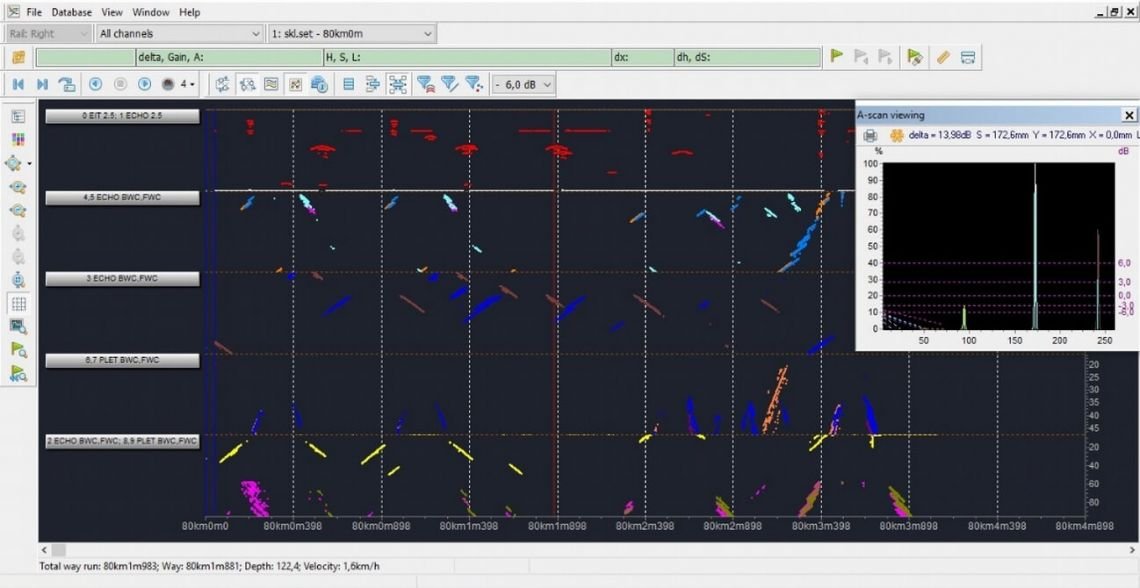

SW for testing, review and analysis of the test results.

SW for testing, review and analysis of the test results.